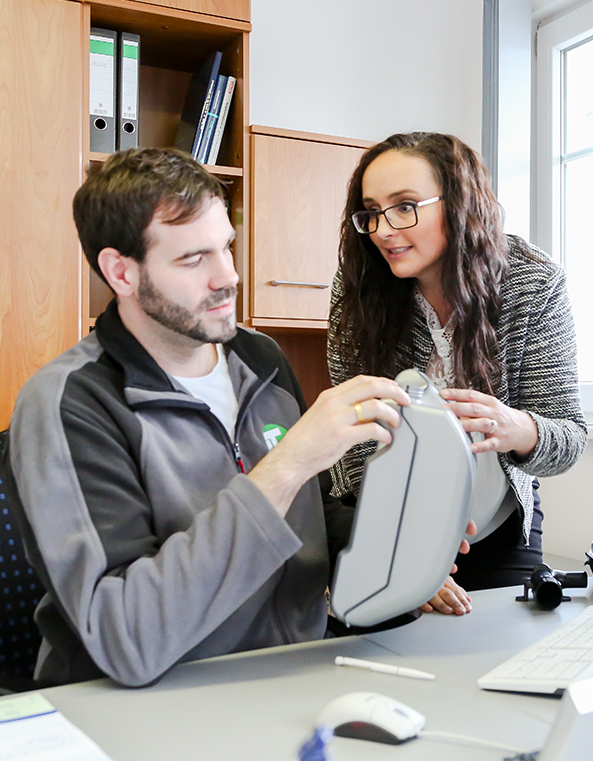

Development and design at Linbrunner –

Top quality from Bavaria

To give your idea the desired shape, we create solutions that are technically superior and cost effective. With the help of industry standard file formats we can produce all the production data required for manufacturing in 2D and 3D using our SolidWorks and ZW3DCAD programmes. Not only do you benefit from the wealth of experience we have in the field of design and fabrication in terms of CAD modelling: our expertise and ideas are also channelled into the product development phase.

From the planning stage to the finished product, at our facility each step in the process is taken with speed and precision. Your idea is given top priority, from start to finish. We offer an all-round service specifically tailored to your needs – from design, mould making and fabrication through the trimming and system supplier services to the final product.

Environment and quality management at Linbrunner

As a family-owned company we willingly take responsibility for the next generation. Almost 100% of our plastic waste is reprocessed and used in our raw-material cycle as regenerated plastic sheeting. This sustainability concept is very important to us – and it is an approach that we also take in other areas. Over 50 per cent of our electricity supply is provided by our own regenerative power supply system. In this regard, Linbrunner has been relentlessly forward-looking in its determination to promote ecologically sound practices.

The best processing method for moulded parts

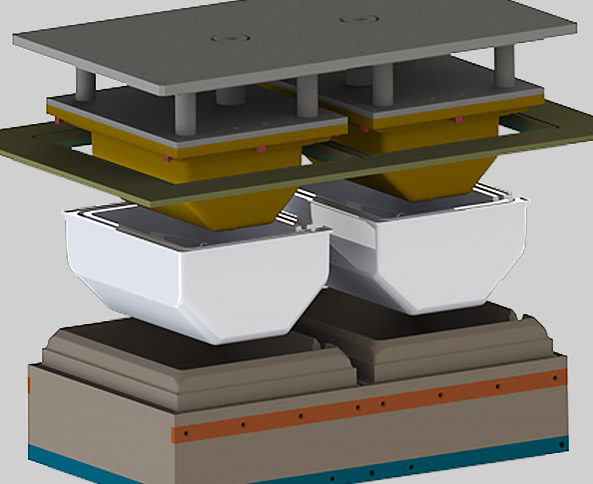

Twin Sheet Forming

The twin sheet thermoforming process at Linbrunner involves clamping two sheets of plastic into a carriage and heating them on both sides..

Learn more

Single-sheet forming

The single-sheet thermoforming process at Linbrunner involves clamping a sheet of plastic into a carriage and heating it on both sides. At the end of the heating..

Learn more